- kamatamogh@airochem.co.in

- +91 9011068031 / 9822833300

Centrifugal Fans

Setting New Benchmarks in High-Performance Centrifugal Fan Manufacturing

At Airochem, we are committed to delivering precision-engineered industrial fans that meet the highest performance standards. Our journey in fan development began with building in-house test rigs and acquiringinstrumentation such as precision manometers and Grade 1 electrical measuring instruments. These advancements laid the foundation for our success.

Stepping into Boiler Fan Manufacturing

By 1985, we entered the competitive field of boiler fan manufacturing, facing formidable challenges from international players with decades of expertise. Rising to the occasion, our team launched an efficiency enhancement program, driven by innovation and engineering excellence.

Key Achievements Include :

- Development of 140 fan models using logarithmic blade shapes to build comprehensive test data.

- Adoption of cutting-edge tools like Solid Edge, enabling precise and efficient fan design.

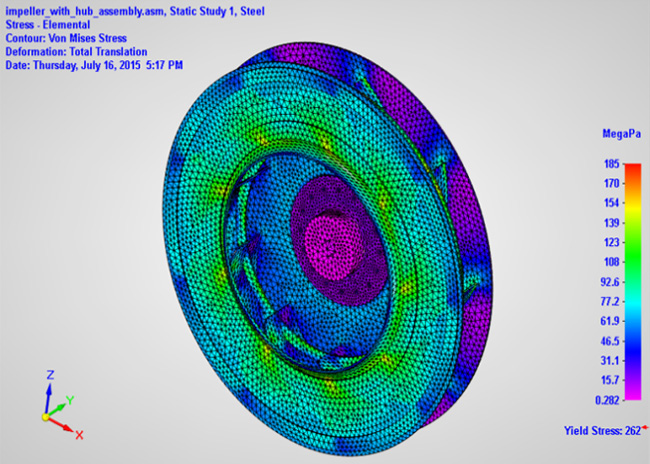

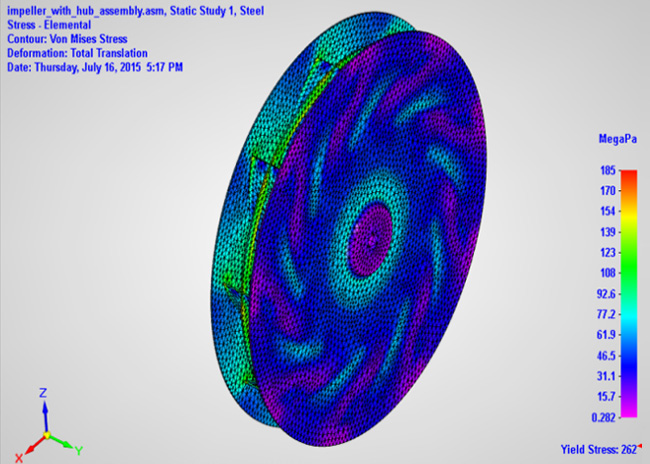

- Utilization of CFD analysis (outsourced for optimization) to ensure competitive or superior performance.

Technical Specifications and Capabilities

Our industrial fans are designed to handle a wide range of applications, offering :

- Airflow Capacity

Up to 1 million cubic meters per hour. - Fan Sizes

Diameters up to 3.5 meters. - Pressure Handling

Up to 3000 mmWG. - Power Requirements

Up to 3000 kW. - Blade Configurations

- Backward Curved

- Straight Inclined Backward

- Radial Blades

Advanced Features and Customizations

- Sealing Options

- Simple shaft seals.

- Labyrinth seals.

- Carbon shaft seals.

- Specialized Constructions

- Flameproof fans for hazardous environments.

- Split fan housings with two-sided shaft bearings for high-power applications.

- High Efficiency and Low Noise

- Fans achieve efficiencies up to 91%, thanks to advanced aerodynamic designs and engineering.

- Noise levels are minimized to comply with industrial standards.

- Structural Stability

- Large fan structures undergo rigorous stability analysis, ensuring long-lasting, trouble-free operation throughout their lifespan.